Analysis of processing technology of pearl foam profiled piece

Shanghai Guer Yi packaging Products Co., LTDProcessing technology of pearl foam profilers: Generally, according to the size and stability of order quantity, there will be different process planning and equipment configuration requirements. According to different order quantity, we will make the following distinctions for the moment

Class A: Big customer orders (single quantity: more than 10,000 pieces and stable delivery)

Category B: General and regular order (single quantity: 1000 pieces -- order between 10000 pieces)

Category C: Small orders (orders within dozens to thousands)

In the processing of pearl foam profilers, more than 90% of the processes are as follows:

Blanking → stamping → blanking → bonding → packaging → warehousing.

Stamping, discharging and bonding processes are the most core processes in the deep processing of pearl foam and cotton, and the three processes that cost the most labor. Therefore, different processing equipment will be adopted in combination with different order quantities, which will directly affect the production cost and quotation of the products

Currently on the market

Production equipment corresponding to stamping process:

A: All kinds of hydraulic presses (cheaper)

B: Special servo motor driven stamping equipment (combined with customized die, can realize automatic waste discharge, high price)

Bonding process corresponding equipment

A: According to the degree of automation, it can be divided into manual, semi-automatic and automatic.

B: According to the working principle or characteristics, it can be divided into: hot air bonding, hot plate bonding, hot melt bonding, etc

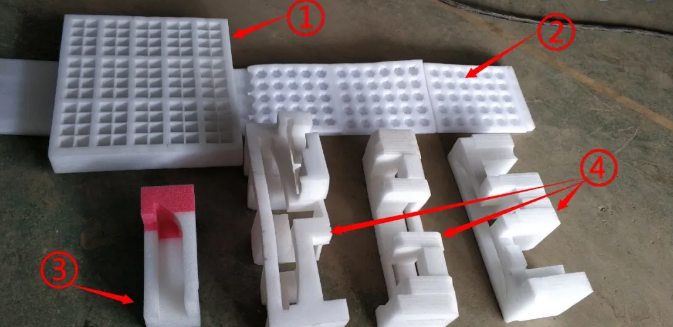

The following is the analysis of the relationship between the two products (order quantity, process and quotation) as shown in the figure

Products 1 and 2 above

Production process is generally: cutting blanking, waste, adhesive packaging

But because the order quantity is not the same, USES the different processing equipment, USES the man-hour completely different, produces the product quotation to differ greatly also

| Order type | Use equipment for each process | Have working hours | ||||

| cutting | stamping | waste | laminating | packaging | ||

| A large order | Cut in batches of fixed size No material waste |

Stamping - waste - fit into one body forming | Pipeline-scale packaging | 6 minutes or so | ||

| Class B General order | Cut in batches of fixed size No material waste |

Single bed stamping | Human waste | Artificial joint | Conventional packing | 11 minutes or so |

| Small Order C | Spot cutting Waste of material |

Single bed stamping | Human waste | Artificial joint | Conventional packing | 15 minutes or so |

Current Position:

Current Position: